Customized CNC Punching Marking And Shearing Production Lines Suitable For A Variety Of Metal Profiles

Applicable Industry:

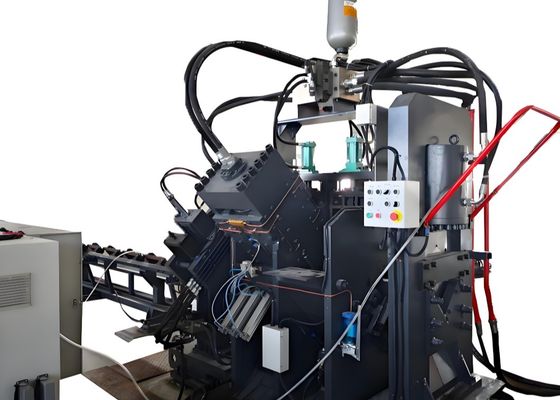

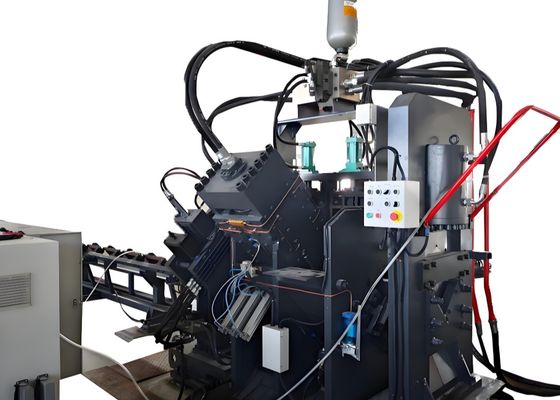

JNC series high speed cnc angle punching, marking and cutting production line is mainly composed of punching unit, marking unit, cutting unit, transverse conveyor, rotating conveyor, feeding conveyor, unloading conveyor, CNC feeding carriage, hydraulic system, electrical system, pneumatic system and so on. This production line is mainly used for the automatic processing of angle steel in tower industry. The processing process is numerically-controlled and the operation is very convenient. It can realize the automatic, high-precision, multi-varieties and mass production.

Specifications:

| Model |

JNC1010 |

JNC1412 |

JNC1616 |

JNC2020 |

| Angle size (mm) |

40х40х3~

100х100х10 |

40х40х3~

140х140х12 |

40х40х3~

160х160х16 |

50х50х4~

200х200х20 |

| Max. Punching (Dia. х Thi.) (mm) |

Φ26х10 |

Φ26х12 |

Φ26х16 |

Φ26х20 |

| Punching force (kN) |

630 |

630/1000 |

1000 |

1000/1200 |

| Marking force (kN) |

630 |

630/1000 |

1000 |

1000/1200 |

| Cutting force (kN) |

1000 |

2000 |

3000 |

2200/4300 |

| Max. length of blank (m) |

12 |

12 |

14 |

14 |

| Max.length of finished (m) |

8 |

8 |

12 |

12 |

| Punches per side |

2 |

2 or 3 |

3 |

3 |

| Group of marking letters |

4 |

4 |

4 |

4 |

| Number of letters per group |

12 |

12/18 |

18 |

18 |

| Character size(mm) |

14x10x19 |

| CNC axes |

3 |

| Cutting mode |

Single Blade |

Double Blade or Single Blade |

| Cooling method |

Water cooling/Air cooling/Oil chiller |

| Angle feeding speed (m/min) |

80 |

80 |

80 |

60 |

| Programming mode |

Lofting software or instruction programming |

| Overall dimension (m) |

About 25x6.5x2.5 |

About 25x6.5x2.5 |

About 32x7x3 |

About 32x7x3 |

The above parameters can be adjusted and changed according to customer's specific requirements.

Product Features:

1. There are three or two sets of punching unit, which can be installed with three kinds of punches with different diameters. The three sets of punching dies are moved by numerical control to change the stadia. It can punch not only round holes but also oval holes. Its fast feeding and punching speeds improve production efficiency. For a 50×50×4mm angle steel, the output is 9-10 tons every eight hours.

2. The marking unit is closed with good rigidity. The marking unit has four sets of cassettes, which is chosen by programming and the typing stadia can be set at will. In addition, can choose the disc typing method. The disc typing has 10 rows and automatically selects characters without manual intervention, which greatly improves typing efficiency.

3. The cutting unit adopts single blade shearing which is popular with large shearing force. There is no waste in each cutting and the cutting surface is neat and smooth. The blade box has an open door design, which makes blade changing quick and safe.

4. The horizontal material table transfers the angle bar to the rotating material rack, which is driven by motor and reducer to place the angle bar steadily on the feeding conveyor.

5. The workpiece is held and fed by CNC feeding carriage with high positioning accuracy. CNC feeding carriage is driven by servo motor with photoelectric encoder feedback, closed-loop control.

These specimens, sourced from the angle steel punching, cutting, and marking machine line, encompass the standard specifications and processing scenarios commonly adopted in the angle steel tower sector. They allow users to directly evaluate the equipment’s processing quality, precision capabilities, and craftsmanship standards.

In the construction of ultra-high voltage (UHV) transmission lines—where transmission towers must withstand extreme meteorological conditions and heavy loads—this equipment performs a critical role in processing the angle steel components that form the towers’ main framework. It reliably carries out drilling and stamping operations on the angle steel used for tower bodies, cross-arms, and other key structural elements. This ensures precise dimensional accuracy and robust connectivity, thereby securing the overall structural stability of the transmission towers.

Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!  Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!