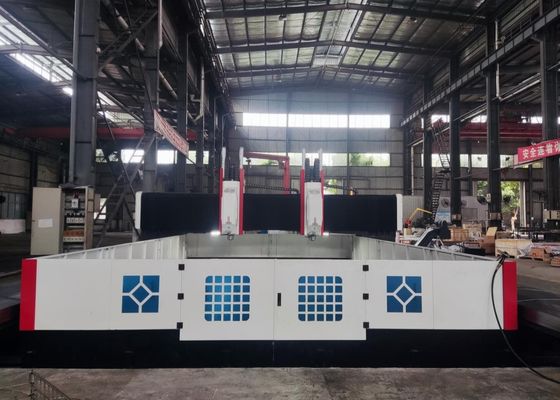

3000x2200mm Werkstukgrootte CNC Plaatboren en frezen BT50-150 Spindel Taper

Toepassing:

De CNC-bor- en freesmachine voor portiervorming is voornamelijk ontworpen voor het boren, kamperen, aftappen en frezen van platen en structurele onderdelen, met inbegrip van flenzen, schijven, ringen,en andere werkstukken met een dikte die binnen het bereik van de effectieve verwerking van de apparatuur valtHet maakt het mogelijk om gaten en blinde gaten te boren, zowel op enkelmateriaal als op samengestelde materialen.Het gehele bewerkingsproces wordt digitaal bestuurd voor uitzonderlijk gebruiksgemak, ondersteunt geautomatiseerde productie, hoge precisie, multi-variëteit verwerking en massaproductie.

Specificaties:

| Grootte van het werkstuk |

LxW |

3000x2200 mm |

| Hoogte van het scharnier |

600 mm |

| Werkbank |

T-slotbreedte |

28 mm |

| Boringkrachtkop |

Qty. |

1 |

| Spindelconic |

BT1 gelijke behandeling BT1 gelijke behandeling |

| Max.boorddiameter |

Φ50 mm |

| De diameter van de kraan |

M3-M24 |

| Spindel snelheid |

30 tot 3000 r/min |

| Vermogen van de servo-spindelmotor |

22 kW |

| Afstand van de onderkant van de spindel tot de werktafel |

200-600 mm |

|

zijdelingse beweging van de aandrijfkop(X-as)

|

Max.horizontale slag |

2200 mm |

| Laterale bewegingssnelheid |

0~8 r/min |

| Servomotorvermogen voor zijdelingse beweging |

2.4 kW |

| Lange gang van de galerij (Y-as) |

Max. voedingsslag |

3000 mm |

| Bewegingssnelheid van de voeding |

0~8 m/min |

| Vermogen van de voedingsservomotor |

2x2,4 kW |

| Verticale voedingsbeweging (Z-as) |

Max. slag |

1000 mm |

| Bewegingssnelheid |

0~8 m/min |

| Servomotorvermogen |

2.4kW (rem) |

| Gelijktijdige positiebepaling |

X/Y/Z/A/B/C |

± 0,015/1000 mm |

| Gelijktijdige positiebepaling in drie assen |

X/Y/Z/A/B/C |

±0,01/1000 mm |

| Algemene grootte |

LxWxH |

6500x4000x2700 mm |

Productkenmerken

1. Machinebed en werkbank:

De machinebed en de werkbank zijn gegoten staal (HT250) van één stuk.Ze hebben een uitstekende dynamische en statische stijfheid met geen vervorming.Het werkbankoppervlak is voorzien van nauwkeurig bewerkte, optimaal gerangschikte T-slots om het werkstuk makkelijker te sluiten.Twee sets van hoge precisie lineaire gidsen zijn gemonteerd aan beide zijden van het bed basis, waardoor de kracht gelijkmatig wordt verdeeld over de geleidingsschuivers en de stijfheid, de treksterkte en de drukweerstand van de werktuigmachine aanzienlijk worden verbeterd.Het aandrijfsysteem maakt gebruik van wisselstroomservomotoren die zijn gekoppeld aan precisie-balschroeven voor dubbelzijdig rijden, waardoor de Y-asbeweging van het portier mogelijk wordt gemaakt.

2Mobiele poort:

Het mobiele portier is gemaakt van gietijzer (HT250). Twee sets ultra-hoge dragende rollende lineaire gidsen zijn aan de voorzijde van het portier gemonteerd.Een precisie bol schroef samenstelling gekoppeld aan een servomotor stelt de kracht kop schuifplaat te bewegen langs de X-asDe schuifplaat van het aandrijfkopje is voorzien van een boorkrachtkop.met een vermogen van meer dan 50 W,.

3Mobiele zadel:

Het mobiele zadel is een precisie gietijzeren constructiecomponent.met een vermogen van niet meer dan 10 W,. Het gewicht van de boorkrachtkop wordt in evenwicht gebracht om de schroefbelasting te verminderen en de levensduur van de kogelschroef te verlengen.het mogelijk maken van acties zoals snelle vooruitgang, snelle omgekeerde beweging en het stoppen van de krachtkop, samen met automatische chipbrekende, chipverwijderende en pauzefuncties.

4- Boorkop:

De boorkrachtkop maakt gebruik van een speciale servo-spindelmotor, die de kracht doorgeeft aan een gespecialiseerde precisie-spindel via een tandrijke synchrone riem voor het verhogen van het koppel.De spindel is geconfigureerd met Japanse hoekcontactlagers in een zesrijke structuur (vier voor en twee achter)De spindel is uitgerust met een pneumatisch gereedschapswisselsysteem en zorgt voor een snelle en handige vervanging van het gereedschap.Voedingsbeweging wordt aangedreven door een servomotor gekoppeld aan een kogelschroefDe X- en Y-assen ondersteunen de koppelingsactiviteit en nemen de semi-gesloten luscontrole aan, waardoor lineaire en circulaire interpolatiefuncties worden gerealiseerd.De spindel is voorzien van een BT50 taper gat en is uitgerust met een hoge snelheid roterende gewricht, ondersteunt hogesnelheids U-boorverwerking met koelvloeistoftoevoer door middel van spindel.

Deze hoogwaardige industriële apparatuur, gespecialiseerd in het boren en markeren van platen en platen,met een vermogen van meer dan 50 W,- speciaal ontworpen voor het verwerken van werkstukken, met inbegrip van flenzen, schijven, ringen en platte platen,het bevat een kernvereiste dat de dikte van dergelijke werkstukken strikt moet overeenkomen met de vooraf ingestelde effectieve bewerkingsspecificaties van de machine.

In installaties voor de vervaardiging van staalconstructies wordt met deze apparatuur nauwkeurig boren en frezen van structuurplaten en verbindingsonderdelen uitgevoerd.waardoor een solide basis wordt gelegd voor de stabiele montage van stalen framesBinnen de windenergie-sectorhet biedt hoogprecise bewerkingsoplossingen voor windturbine torens en flenzen, een essentieel proces dat garandeert dat deze onderdelen bestand zijn tegen harde omgevingsomstandigheden (e)Voor de bouw van bruggen verwerkt de apparatuur bruggrijzen en dragerbeugels, waardoor een stabiele,duurzame verbindingen die zijn ontworpen om dynamische belastingen te weerstaan gedurende de lange levensduur van de brug.

Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!  Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!